The Process

Probably one of the most useful outlines we can provide for Takt is the step by step outline for how to create one. We hope to help you visualize the process in this blog post. But first, here is the list of steps in summary:

· Identify your start and end date.

· Research your drawings.

· Identify the general flow of the project based on known constraints.

· Identify preliminary Takt zones.

· Identify preliminary Takt time.

· Pull plan a typical sequence to start.

· Create the Takt sequence.

· Create the Takt phase.

· Identify logistics flow.

· Optimize the throughput with Little’s Law.

· Network phases together.

· Develop work steps.

· Trigger planning buffers in the system.

· Add buffers.

· Create standard work.

· Identify bottlenecks.

· Verify with trade partners.

· Create logistics plan/drawings.

· Create Takt zone maps.

· Perform a risk analysis.

· Create a Basis of Schedule (BOS).

· Align procurement.

· Review in a “fresh eyes” meeting.

· Create roadblock tracking maps.

· Track historical production.

· Add a TPNR.

One of the best ways to get into this system is to create your first Takt plan, so let’s get started. But first, we want to explain a few concepts of overall structure.

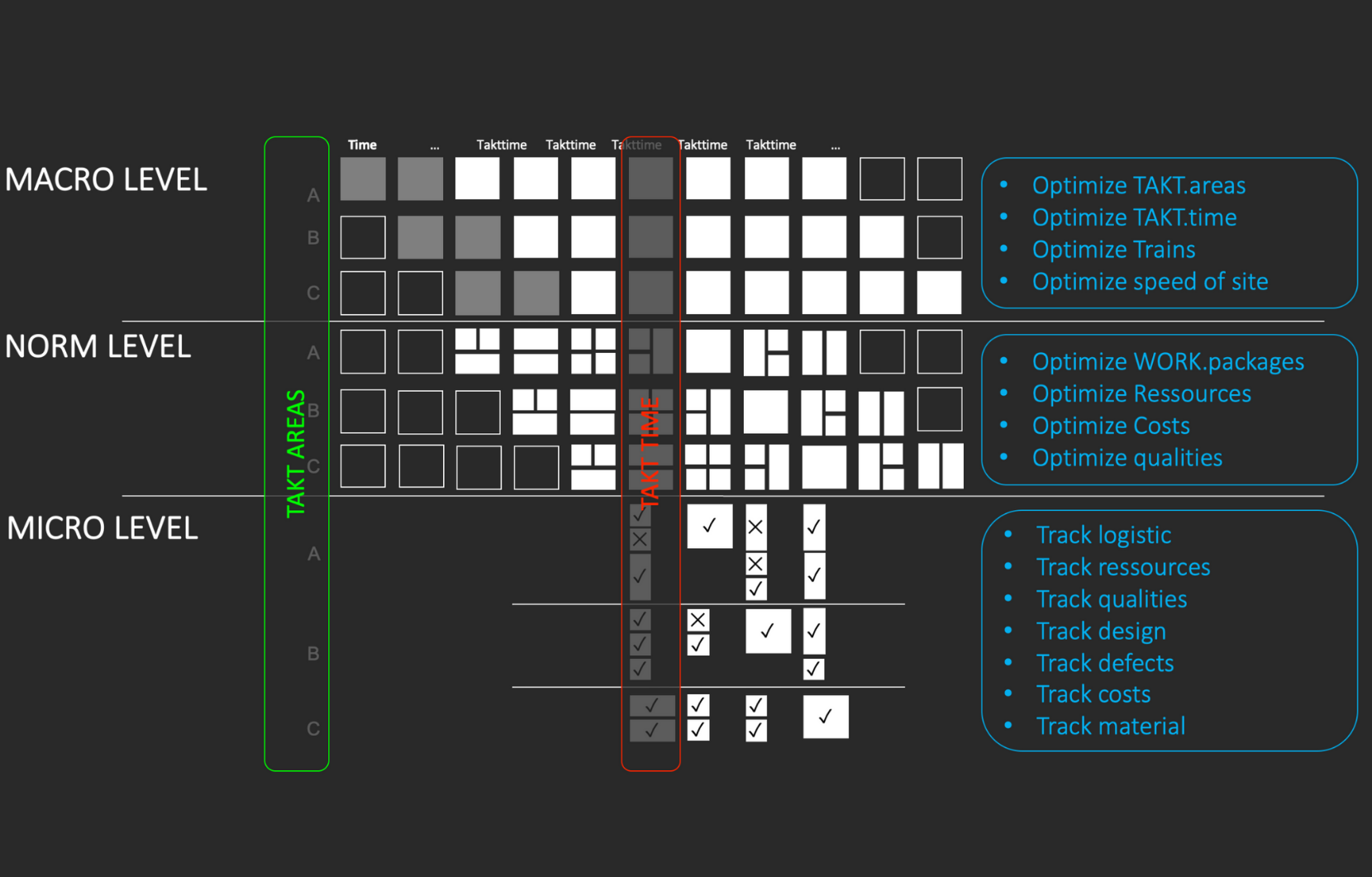

There are three levels of Takt plan development:

● Macro level, the process analysis – In the macro-level, the overall Takt plan is created.

● Norm-level Takt planning – In the norm-level, the Takt plan harmonization takes place.

● Micro level – This level of Takt planning is crucial to the system and cannot be omitted. In this step, the management of Takt control takes place.

Identify Your Start and End Date

Some projects come with a stipulated start and end date. Some projects’ start and end dates need to be identified through your efforts of creating a Takt plan. To be successful in creating your plan, you will start here and know what constraints you have as you begin the planning process. Then you can begin to…

Research Your Drawings

This step may seem like a given, but it needs to be said. One of the geniuses of Takt is that it gives our builders back the time they need to carry out the basics of a builder which means studying the drawings each day, forward planning in the schedule, and reflecting daily. As the builder studies the design and gets a feel for the flow, the sequence, and the general strategic approach for the project with others, he/she will immediately see and identify the flow of the project. This is to start to…

Identifying Flow

Builders can get a feel for the general flow of the project after digging into the drawings. Constraints like staging, material flow, material access, adjacent structures, hoisting, and project access will begin to form a picture of how the project will need to generally flow. Does the construction begin from east to west, or west to east? Does the interior run from top down or bottom up? This general idea of how the project will flow as the builder visualizes construction will begin…

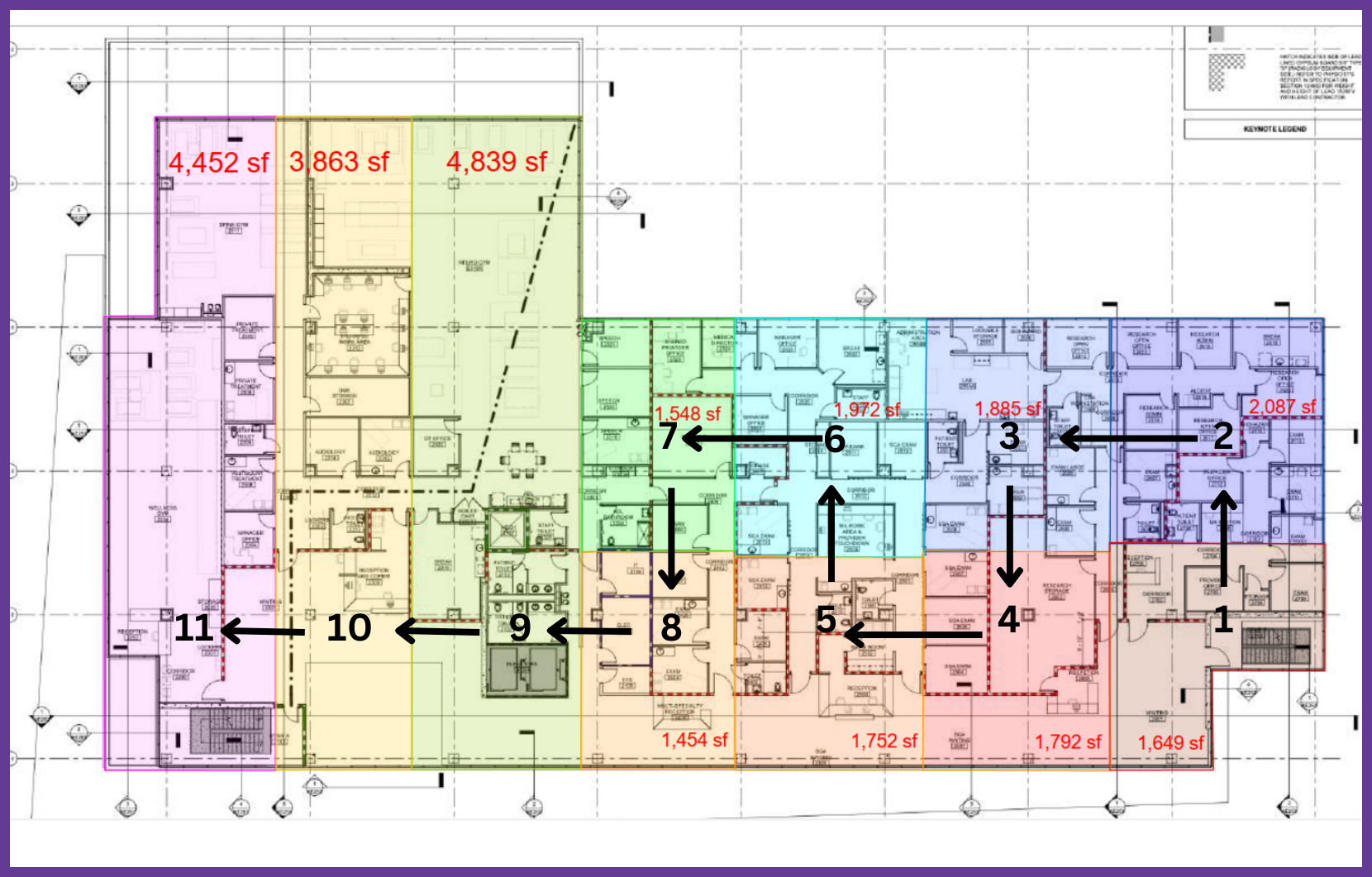

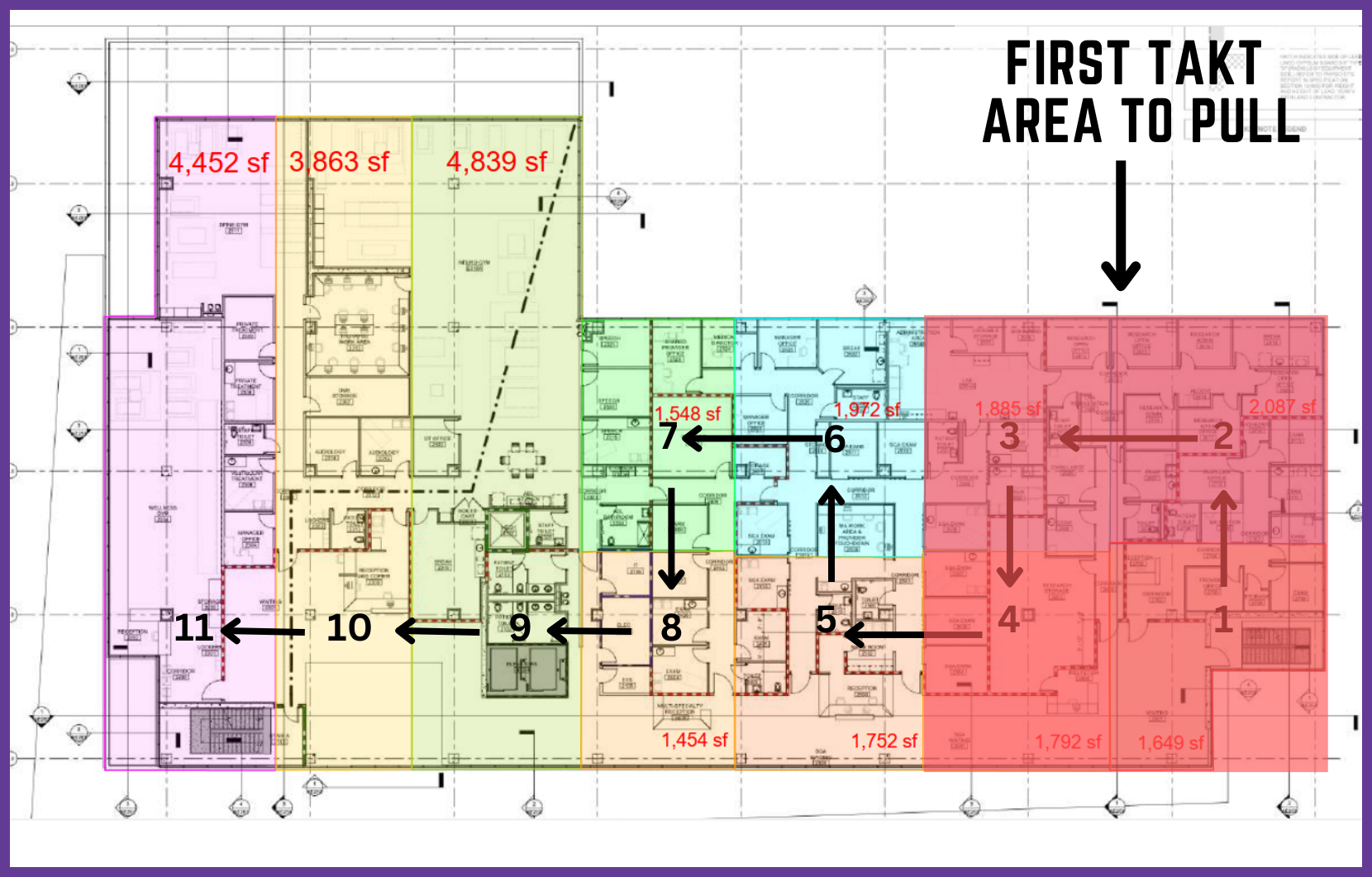

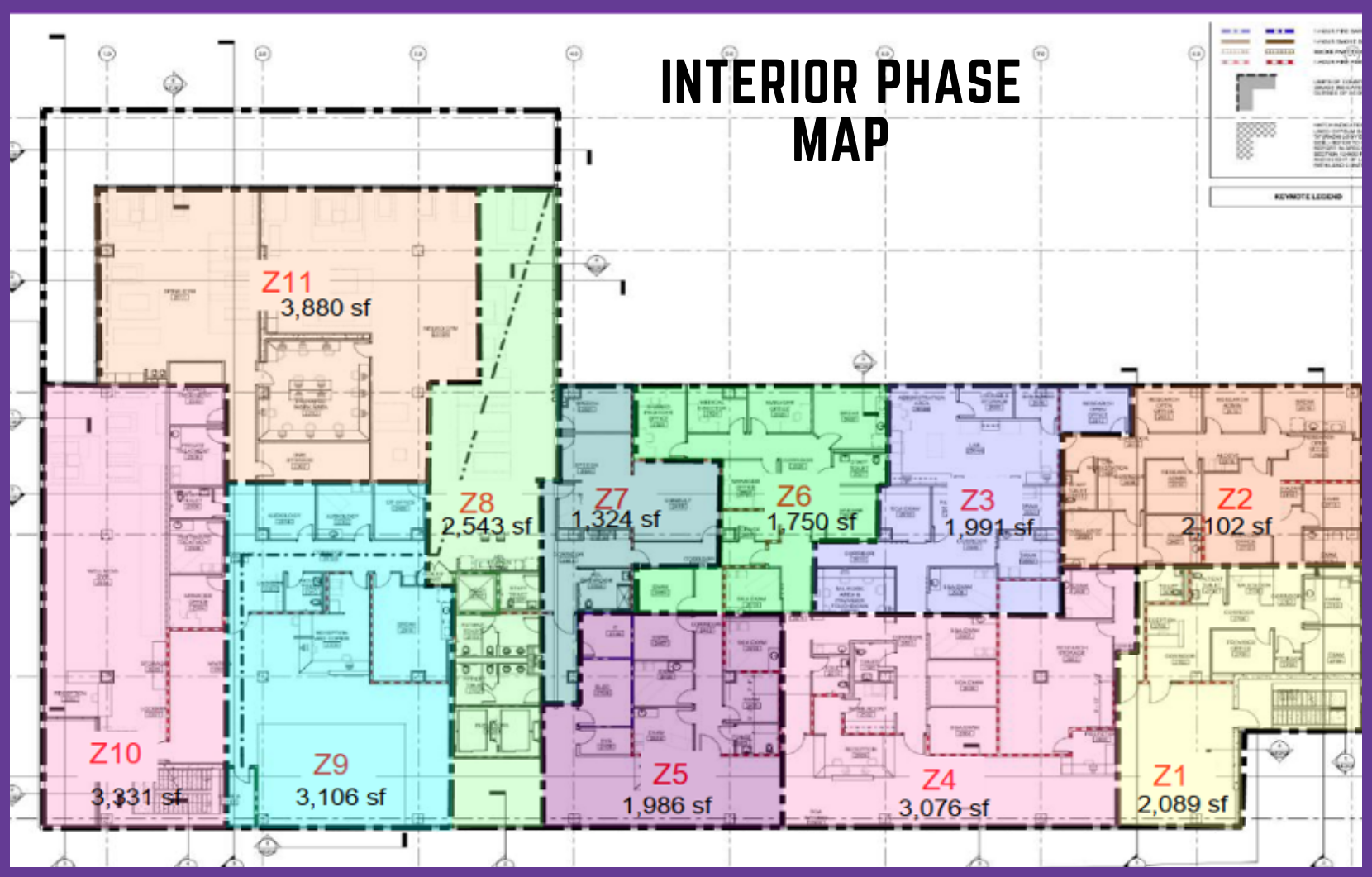

Identifying Preliminary Takt Zones

Takt zones, sometimes known as geographical areas, production areas, or sequences, are the areas defined within the phase to identify work that will be scheduled on a rhythm per the Takt time. To get portions of work broken down to fit within a drumbeat, we must break the work up into zones that can be completed according to that drumbeat. This is easy to do, especially if the first planners know the general direction of the flow and how much area can be completed within the Takt time. So, the first planners literally guessed-and yes, I said guess-on the right size areas needed to break up the floor, exterior, or general work area. Once we do that, we can…

Pull Plan the Representative Zone

Now that we have a preliminary Takt zone size, we can outline the sequence of one representative Takt zone. Before you begin the pull plan, you may want to consider getting quantities for the representative area to better help trades visualize the commitments they are making.

The team will collaboratively pull the sequence inside the first representative Takt zone by following these steps:

Ask trades to come prepared with their activities, tags, or Sticky Notes ahead of the meeting and to think about what each activity needs for them to begin.

When opening the meeting establish the following:

1. The Time Frame

2. The trade colors

3. The Sticky Note format

4. The parking lot

5. The rules of the meeting—we recommend asking the group to make the rules of the pull plan together. Common rules teams list are:

1. No one touches each other’s tags

2. Make commitments to each other

3. Work from the milestone back

4. Turn the sticky to a diagonal if it has an unmet constraint

5. Sidebar non-pertinent conversations

6. Each trade will ask for the preceding tasks to be placed on the board

7. And so on…

Begin building the sequence of the pull plan until there are no more predecessors or needed activities

When the sequence is done, the team can work the plan forward to ensure it fits within the target duration and also to introduce parallelization of activities. The team will ensure the activity sequence is optimized.

Work Packaging & Leveling

Once this is done and the first representative Takt zone is pulled, it is time to organize these into work packages and Takt wagons in a preliminary manner. When observing the sequence, it may become clear what average Takt time each activity fits within. The duration of each work package will inform you what Takt wagon it needs to fit within.

Package them into Takt sequences

A Takt sequence or Takt train is a sequence of Takt wagons. Each Takt wagon includes one or more work packages, and each work package contains multiple work steps. By this point, stickies from the pull plan sequence have become either a Takt wagon, a work package, or a work step depending on size and how it is packaged. Knowing how they translate comes from facilitation and experience but generally, if the activity was a large summary of a general scope of work that occurs by itself in a Takt time scale, it may become a Takt wagon. If it is a specific scope of work that summarizes steps that work in the same area as another scope, it would become a work package. If the activity was a detailed step as a part of a scope of work then it is likely a work step. For now, we need to know what Takt wagons will fit within our single representative Takt zone within one Takt time.

The current work steps or work packages should all be generally packaged within Takt wagons. This sequence or train is then placed in the Takt plan within the Takt time scale. These then combine to make a…

Build your Takt Phase

A Takt sequence or Takt train is a sequence of Takt wagons. Each Takt wagon includes one or more work packages, and each work package contains multiple work steps which ends up as a horizontal summary of the work in that area. Now we need to show the relationship between the other Takt zones. This is where we copy the sequence down to other rows in the Takt phase at the right stagger. The stagger is important because the stagger between the start of each train may not follow only one Takt time. If there is a Takt time of 5 days, each train may not be offset from each other by 5 days. Rather, they may have a stagger of 10 days and use two Takt times between starts. Either way, we will copy these sequences down at the correct stagger. When you have completed this you will see if it generally fits within the overall project duration or phase duration, but only in a preliminary sense. Next, we must enter a step called…

Takt Optimization

Now you have preliminary Takt zones, Takt time, and sequence. But remember, these are all preliminary. We need to do one more thing, and it is super fun and rewarding. Here is a part of the true power of Takt planning. To optimize your phase we need to introduce a formula:

(TW + TZ -1) x TT = duration or throughput time

This means the number of Takt wagons plus the number Takt zones minus 1. That sum multiplied by the Takt time in days equals your phase duration or throughput time.

We need to confirm the number of Takt wagons, Takt zones and the Takt time in our phase before moving forward by using this formula and analysis. Now that you know your ideal throughput time, confirm this with the trades and adjust your plan accordingly. Now that we have completed this optimization, it is time to…

Network your Phases Together

It is important to see all phases of the project and how they network together. This should be done on one sheet regardless of the size of the format. We want to confirm the proper interdependence ties between design, permitting, coordination, contracting, procurement, mobilization, foundations, superstructure, exterior, interior rough-in, interior finishes, roofing, commissioning, site work, and final inspections. Without this, we do not have a proper overall project duration with a reasonable end date that will prevent a crash-landing.

The mobilization phase should provide enough space before foundations can mobilize and begin. The foundations should be far enough along before the superstructure can go vertical and the vertical crews must be high enough or complete so the exterior can begin. The exterior framing should be complete enough that interior walls and demising walls can be framed. Exterior dry in should be done in enough time for drywall to begin and for commissioning to begin, the building must be enclosed and HVAC must be available.

This is where Takt planning as a visual is genius. The coordination and peer reviews and the eventual “fresh eyes” meeting can focus on these transitions and how they support the overall flow of the project. At this point we need to remember that we should continually focus on…

Buffer Management

No schedule should ever plan on 100% productivity or efficiency. This would mean we are planning for no variation in construction which would not be responsible. Greg Howell wrote an abstract for the IGLC entitled “Causes of Time Buffers in Construction Project Task Durations” in which he describes a survey that he and three of his colleagues performed. In this survey they found 47 reasons for project buffers such as unforeseen conditions, labor shortages, supply chain variances, and weather to name a few.

There must be buffers in the plan. There are three types of buffers that can be used within Takt plans which include material inventory, capacity and time.

Without buffers we enter a push environment and spiral into a failing situation with overburden, unevenness, and waste (ultimately taking more time). When we have enough buffers, teams can constantly stay in flow. This is due to buffers allowing for statistical fluctuations as described in the Theory of Constraints. If you have buffers, you can gain time. If you don’t have buffers you will lose time. It is a paradox, but it is true. A plan without Buffers is destined to fail. Once you have the right buffers, you can…

Create Finalized Takt Zone Drawings

You should have Takt zone drawings for all major phases. Mobilization, foundations, superstructure, exterior and interior work will all have phasing. These Takt zones show the amounts of work that need to be completed according to the Takt time. These drawings should accompany the contract and bidding documents as an exhibit to ensure the system has been properly priced, included in the bid, and aligned with procurement efforts. Once in construction you will use the…

Roadblock Tracking Maps

Roadblock tracking maps are crucial to the system. They are used to show the differentiation between typical and non-typical areas and also to track roadblocks visually throughout the system. They can be based on the Takt zone maps and can either be physical drawings with plexiglass coverings on your conference room wall or a Bluebeam Project to which everyone has access. The point is to spend most of the time focusing on the removal of roadblocks as the number one standing tactical order.

Once you can see them visually you can even use scrum to clear the roadblocks in the most efficient manner.

Conclusion

Although there are more steps to the process, you now have a Takt plan at the fundamental level. One of the best ways to get started is to experiment with a Takt template in Excel and just have fun. If you do not know Excel, this is such an opportunity for you to learn such a critical and amazing tool. As we leave you to take the Takt template for a drive, let’s remember the fundamental requirements of a Takt plan so we can constantly align anything we create with that vision. A Takt plan is…

A visual location-based schedule showing time and space

Showing work, trade, and logistical flow (when, what, where, who, how)

Scheduled on a rhythm

With the appropriate buffers

That stabilizes the pace of work with one-process flow and limiting work in process

With a reasonable overall project duration

It is a system that creates stability in the field which enables—

Additional team and builder capacity

Consistent crew sizes

Consistent material inventory levels

The ability to find and remove roadblocks ahead of the work

The ability to finish as we go

A solid quality program

Good luck! You are about to enter a completely new world of stability and flow.

If you want to learn more we have:

-Takt Virtual Training: (Click here)

-Check out our Youtube channel for more info: (Click here)

-Listen to the Elevate Construction podcast: (Click here)

-Check out our training programs and certifications: (Click here)

–The Takt Book: (Click here)

Discover Jason’s Expertise:

Meet Jason Schroeder, the driving force behind Elevate Construction IST. As the company’s owner and principal consultant, he’s dedicated to taking construction to new heights. With a wealth of industry experience, he’s crafted the Field Engineer Boot Camp and Superintendent Boot Camp – intensive training programs engineered to cultivate top-tier leaders capable of steering their teams towards success. Jason’s vision? To expand his training initiatives across the nation, empowering construction firms to soar to unprecedented levels of excellence.

On we go!